Cemented carbides with heterogeneous structure

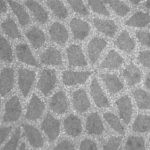

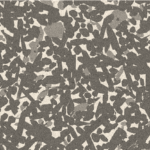

Cemented carbide with heterogeneous structure is a kind of biomimetic material, owning honeycomb like structure through special preparation technique. In this unique structure, core materials with perfect abrasion resistance are separated by boundary materials with relative good toughness. If cracks appear in core materials during the period of service and propagate to the boundary materials, the propagation will be terminated by the tough boundary and the cracks connecting will be avoid. Thus, the fracture resistance and service life of the cemented carbides are effectively improved, as well as the work efficiency and economy of resource exploration and exploitation.

Cemented carbide with heterogeneous structure is a kind of biomimetic material, owning honeycomb like structure through special preparation technique. In this unique structure, core materials with perfect abrasion resistance are separated by boundary materials with relative good toughness. If cracks appear in core materials during the period of service and propagate to the boundary materials, the propagation will be terminated by the tough boundary and the cracks connecting will be avoid. Thus, the fracture resistance and service life of the cemented carbides are effectively improved, as well as the work efficiency and economy of resource exploration and exploitation.

Fine and super fine crystal cemented carbides

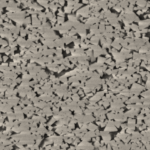

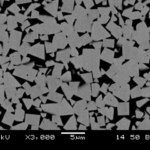

Fine and super-fine crystal cemented carbides are produced by special fine-grain strength process. Compared to traditional cemented carbides, grain sizes are significantly reduced which gives higher hardness and more homogenous microstructure. Its wear resistance and bending strength are increased obviously, thus the problem of the brittleness is effectively settled. These series of cemented carbides are suitable for production of machining tools, wear resistance parts and customized products, and the application field of cemented carbides products is greatly extended.

Fine and super-fine crystal cemented carbides are produced by special fine-grain strength process. Compared to traditional cemented carbides, grain sizes are significantly reduced which gives higher hardness and more homogenous microstructure. Its wear resistance and bending strength are increased obviously, thus the problem of the brittleness is effectively settled. These series of cemented carbides are suitable for production of machining tools, wear resistance parts and customized products, and the application field of cemented carbides products is greatly extended.

New cwha cermet

CWHA cermet materials are kinds of new materials which possess special specifications such as corrosion-, wear-, high temperature- , and oxidation-resistance. These cermet are designed for some extreme environment, which can be used in acid and alkali corrosion conditions and high temperature oxidizing environment. CWHA cermet materials are widely used in the fields of ocean engineering, resource exploration, nuclear power development, and sophisticated weapons. Besides, these cermet are candidate materials and substitute materials of fine mechanics due to its unique properties such as non-magnetic, low density, and bright polished reflective surface.

CWHA cermet materials are kinds of new materials which possess special specifications such as corrosion-, wear-, high temperature- , and oxidation-resistance. These cermet are designed for some extreme environment, which can be used in acid and alkali corrosion conditions and high temperature oxidizing environment. CWHA cermet materials are widely used in the fields of ocean engineering, resource exploration, nuclear power development, and sophisticated weapons. Besides, these cermet are candidate materials and substitute materials of fine mechanics due to its unique properties such as non-magnetic, low density, and bright polished reflective surface.

Nanoparticles-reinforced cemented carbides

Nanoparticles-reinforced cemented carbides are prepared with additives and nano-particles are produced by special subsequent treatment. Due to the homogeneous distribution of nano-particles in the matrix, the better strengthening effect is reached. The results of experiment show that both abrasion resistance and toughness of cemented carbides are significantly increased after nanoparticles-reinforcement. These series of cemented carbides are suitable for mining, oil drilling, shields and cold upsetting dies.

Nanoparticles-reinforced cemented carbides are prepared with additives and nano-particles are produced by special subsequent treatment. Due to the homogeneous distribution of nano-particles in the matrix, the better strengthening effect is reached. The results of experiment show that both abrasion resistance and toughness of cemented carbides are significantly increased after nanoparticles-reinforcement. These series of cemented carbides are suitable for mining, oil drilling, shields and cold upsetting dies.

Advanced manufacturing facilities

“CISRI Production Base is located in National Industrial Test Base of Fine Metallurgy Varieties, which is right closed to Zhuozhou Exit of Beijing-Hong Kong-Macao Highway (G4).

The base is well equipped with such advanced facilities as high-energy ball mill, isostatic press, high precision extruding & molding machine, pressure dewaxing & sintering furnaces, stress-relaxing devices, and fine-processing equipment, et al.

Furthermore, a high-class dust-free cleanroom facility as an ancillary plant is specifically built for powder processing, efficiently avoiding the contamination by the fine particle in air.

Using such international-leading equipment, a series of high performance cemented carbides can be quantitatively supplied for different service conditions, including inserts, PDC substrates, mining bits, solid rods, central & parallel holes rods, helix holes rods, wires, sheets, molds, customized products and other dimensional accuracy products.”

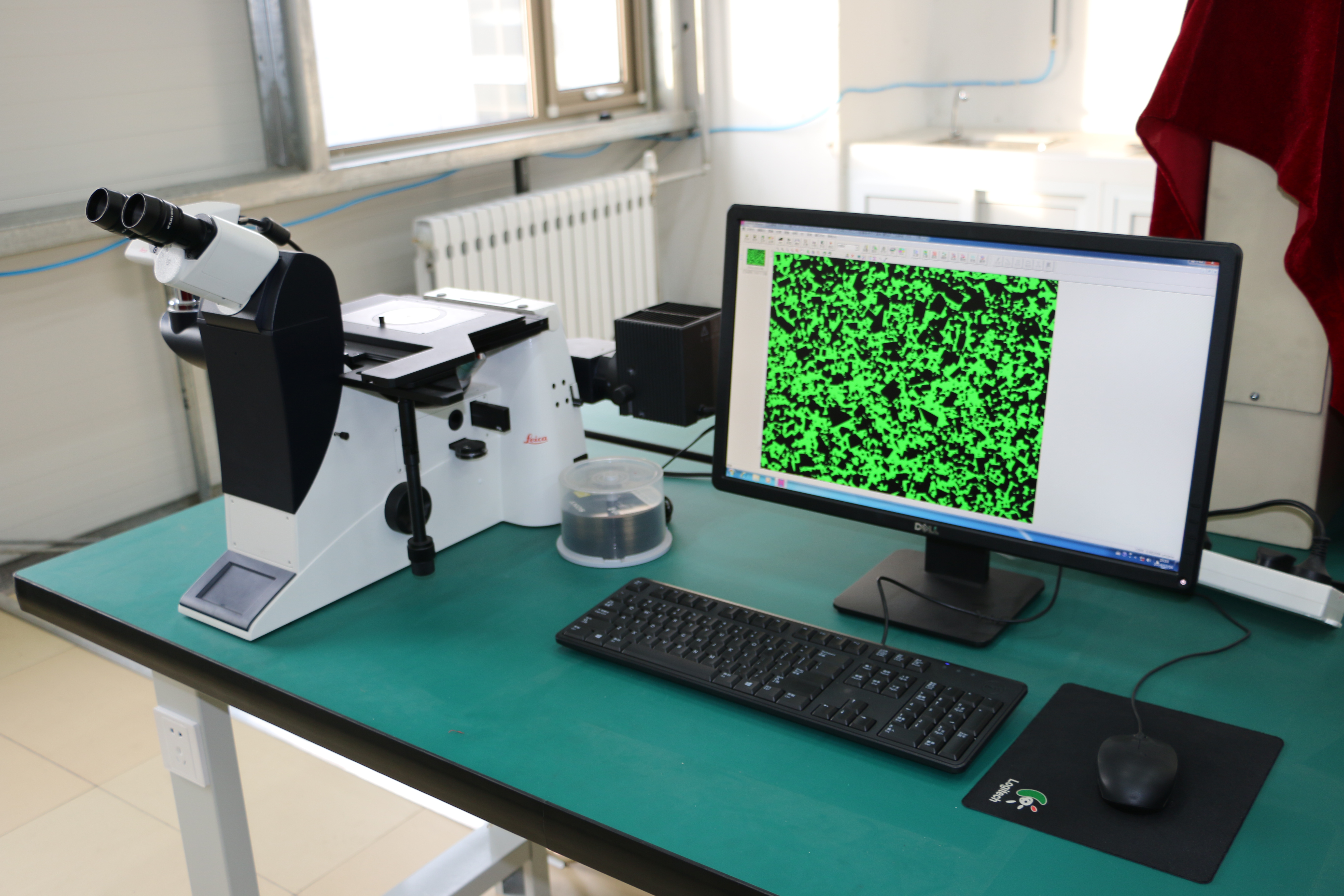

Advanced analytical and testing equipment

Professional analytical & testing laboratory is outfitted for high performance and stability of cemented carbide products. The laboratory is equipped with advanced instruments such as field emission scanning electron microscope (FE-SEM), metallurgic microscope, X-ray diffractometer (XRD), inductively coupled plasma atomic emission spectrometry (ICP-AES), laser particle analyzer, cobalt magnetic meter, coercive force meter, micro-hardness tester, carbon & sulfur analyzer, universal testing machine, spiral angular measurement, and wide temperature range friction & wear tester.

The chemical-, physical-, mechanical-, and magnetic-properties of powders, compacts, and end products can be analyzed and tested on-line or off-line during preparation process, by which efficient data monitoring and feedback information can be obtained.